Methods of Production

We engineer and produce complex industrial ceramic parts for our customers.

On time, and on budget.

Raw materials

Milling/Mixing

Spray/Drying

Forming

Green Machining

Sintering

Grinding

Special process

Inspection

Cleaning

Packing

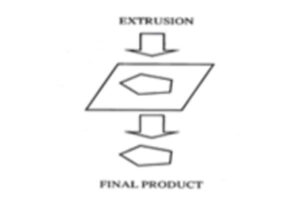

Extrusion

For forcing powder through constricting die, with binder, to have the ficed cross-section for some long object powder either cold or heated.

Injection

By plunger, pressing heated powder to the die, then slowly the mixed binder burnt out by heating afterwards, open the die and have the part and sinter it later.

Isostatic Pressing

By inserting granular power to flexible air-tight container, even pressure generated by surrounding inside liquid, this uniform pressure will produce good product.

Pressing

By putting powder in the die and pressed, applying uniaxial pressure with heating, very tiny residual moisture, for large quantity with high accuracy suitable for simple shape, usually diamond grinding required for finished tolerance.

Slip Casting

By filling of mould, with ceramic particle in liquid to the negative of desired shape, (draing casting) liquid withdrawn from the slip and. have the part.

Request More

Information

For Custom Quote

Commercial Roofing

Built-Up Flat Roof Installation

After Storm Damage

Wood Shake Roof Repair

Risus varius adipiscing nam mauris, sit vel nunc lorem lacus, ut volutpat enim orci molestie est et lorem laoreet sit quis amet, nunc sed quam pretium nibh et, urna proin euismod sagittis.

Residential Roofing

Shingle Roof Replacement

Risus varius adipiscing nam mauris, sit vel nunc lorem lacus, ut volutpat enim orci molestie est et lorem laoreet sit quis amet, nunc sed quam pretium nibh et, urna proin euismod sagittis.

Commercial Roofing

Commercial Skylight Installation

Need A Free Estimate?

Rutrum ut volutpat scelerisque auctor ultrices lectus ultrices ullamcorper massa diam etiam amet a, nulla pulvinar sapien.